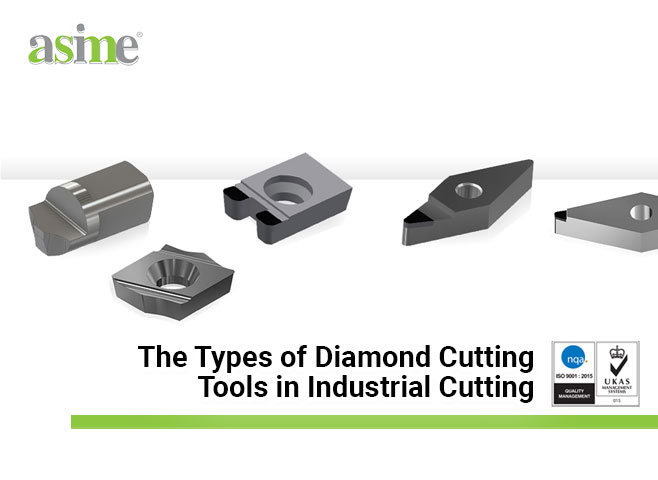

What are Diamond Cutting Tools?

Diamond Cutting Tools or Polycrystalline Diamond (PCD) cutting tools are used to cut aluminium, brass and copper, graphite and other materials like wood, plastic and carbon-fibre-reinforced polymer (CFRP).

So, PCD cutting tools are basically used to obtain high abrasive resistance and high hardness.

Also, PCD diamond tools result in a longer life for the cutter in comparison to conventional cutters. These tools too customize designs to fit your exact measurement specifications.

Types of Diamond High Precision Tools

Reamer

PCD Reamers guarantee excellent surface finish with small margins of error and high accuracy for economical machining compared to a regular carbide reamer.

Using PCD Reamers significantly improve tool life – approximately 10 times longer than the carbide.

On top of that, its high cutting angle shortens the cutting time and increases productivity resulting in higher volume production. So, the best part of using this PCD cutting tool is that you can customise into various forms according to your cutting environment.

Drill

PCD Drills are best in their excellent cutting performance. Because, they have improved surface roughness and hole tolerance for high precision outcome.

Not to forget, the biggest highlight of PCD Drills is that this PCD cutting tool ideally suits the aerospace components and materials. Especially with PCD Step Drills, they are designed for a sharp cut with lower cycle time.

Endmill

On the other hand, the PCD Endmill comes with high rake angle insert that reduces the burr creation for a longer period of time. So, they work at high efficiency when machining with high cutting speed resulting in bigger volume production.

Doing so too improves the surface finish especially with the presence of PCD diamond tool. So, PCD Drills ideally suit for finishing non-ferrous metals and machining reinforced plastics.

Boring Tools

Next, boring tools typically function to enlarge holes. Having PCD Boring Tools, they allow high precision and present excellent finishing quality.

Now, you can use PCD Boring Tools ideally to machine aluminium alloys. To top it off, it is best if you use high rigidity equipment as well as a high precision holder for perfect machining performance.[/vc_column_text]

Forming Tools

PCD Forming Tools, on the other hand, is the solution to the increased complexity of workpieces’ shapes and sizes creation while being able to shorten the cycle time.

The increasing productivity here is due to its long tool life and the usage of complex forms combining copying and multi-stage designs. Also, these industrial cutting tools emphasise enough on an excellent surface finish.

What is the difference between PCD and CBN cutting tools?

Look out for their ultimate functions because the advantage of PCD is mainly its consistently high-quality materials for high precision outcomes. Thus, using it makes the cutting process easier to create tools with the same characteristics.

Polycrystalline Carbon Boron Nitride (CBN) is a high-performance tool material from the Polycrystalline mass that produces tools in a high temperature-pressure process.

You can also find out how PCD Form Tools work in the metal working industry.

Leading Manufacturer of Custom Diamond Cutting Tools

We suggest you consult ASIME, the ISO Certified Precision Tools manufacturer, who has been in the industry for more than 20 years in high-end precision tools manufacturing.

So look no further as we are the top industrial cutting tools manufacturer and are always following DOE and ISO standards. Our tools and services are nothing short of world-class.