ASIME Sdn Bhd, the top cutting tools manufacturer was founded by Fong Kok Hoo in 2001 to meet the growing demand in tool manufacturing. Combining our extensive skills, technical knowledge, and advanced technology, our product line has upgraded to include all kinds of high-grade tungsten carbide cutting tools, diamond cutting tools, PCD, and PCBN cutting inserts.

With a built-up capital of RM370,000, the company has grown by leaps and bounds, establishing a solid reputation among its peers and clients. It is our aim and vision to provide quality products and reliable solutions to the machine tools industry.

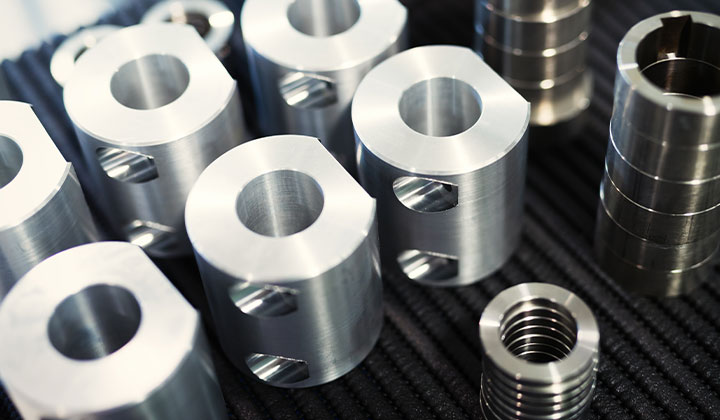

Over the years, we have successfully established a new business to fulfill our growing demand. Now, we are able to produce custom machining parts for manufacturing various industrial parts. These include electronic and automotive machining parts, medical machining parts, optic machining parts, silicone machining parts, and precision molds and dies.

Our Mission

We take pride in offering our clients the best services available in the region, powered by state-of-the-art technology as well as our talented and dedicated staff. In doing so, our group of companies are committed to exceeding expectations and creating customer relationships built on mutual respect, integrity, and trust. You can count on us to deliver cost-efficient solutions on time, every time as your No.1 diamond cutting tools and precision machining parts manufacturer.

Our Philosophy

We aim to be your first choice amongst industrial cutting tools manufacturers and custom machining parts in Malaysia, the region, and beyond by putting passion into everything we do, while ensuring our operations are conducted with great integrity and to high standards. ASIME strives to pursue world-class practices, practicing strict quality control and a commitment to be environmentally aware and responsible. There is nothing we cannot do together when we share the same vision for excellence.

Our Expertise

Cutting Tools Manufacturer

We manufacture a wide range of high-quality diamond cutting tools using the latest machines and technology. From diamond grinding to milling machines to superfinishing, we offer an extensive list of services. We are also readily prepared to offer custom diamond insert cutting tools and expertise to meet your requirements, whatever they may be.

Our Expertise

Machining Parts Manufacturer

We specialize in producing precision machining parts and components for a wide range of industries such as medical, optical, silicone, automotive, electronic, and precision mold and dies. No matter how complicated your part structure is, or how specific your requirements are, we can provide you with solutions.

Our Expertise

Research and Development

Research and development are integral to our business. We are always looking for more efficient methods and better solutions for our clients. Armed with the German GTR Software, our R&D experts are able to perform stress analyses before any tools manufacturing process begins. This ensures quality control and the life span of our tools. We also use computerized machines such as Fanuc and COBORN, which gives us a competitive edge for our custom-made cutting tools.

Our Expertise

Cutting Tools Engineering, Design and Drawing

ASIME design team was established in 2009 to develop and produce custom-made precision equipment and machine tools. Our experienced team with its state-of-the-art computerized design systems is able to provide top-quality, highly reliable solutions for your industry.

In 2010, Asime successfully extended its business to China and ASEAN countries, which is a great international success thanks to our qualified and experienced engineers. Furthermore, our service support team is highly trained with different vendor certifications. All of these guarantee our customers quality services from implementation to after-sales support.

By further harnessing the potential of its global business, Asime strives to further enhance its R&D and Management capabilities, a key driver for future growth.

Industry we Serve

Every vehicle manufactured consists of individual parts that require precision to meet the highest levels of safety and performance. ASIME has a complete line of cutting tools and customized precision equipment for the automotive industry for parts such as:

- Drive shafts

- Transmission components

- Cylinder heads

- Hydraulic elements

- Brake discs

- Connecting rods

- Bearings

- Clutch pressure plates

- Brake drums

Similar to the automotive industry, aircraft are built by placing accurately dimensioned parts and pieces together until they are assembled into an aeronautical mode of transport. Thus, precision should never be an afterthought. ASIME can manufacture tools and machining parts for aviation components such as:

- Turbine housings

- Rings

- Washers

- Turbine blades

- Wheels

- Suspensions

High precision is greatly needed for the medical industry mainly because it involves living beings. Furthermore, medical equipment primarily uses biocompatible and durable material which needs cutting tools and machining parts that can manage its strength such as:

- Surgical scissors

- Biopsy tubes

- Cannulas

- Bone saw

- Medical device components

- Titanium implants

- Collimators

Like the medical industry, the optical field also requires high precision to ensure highly functional components. We understand the unique manufacturing needs of this sector and guarantee high precision optical components such as:

- Beam Expander Cases

- Galvo Mirror System Hardware

- Lens Mounting Brackets

- Fabry-Perot Interferometer Casings

- Shearing Interferometer Casings

- Pockels Cells

- Optical Isolator Components

- Tube Lens Hardware

- CNC turning of stainless steel, copper, aluminum, and brass optical components

Injection molding of Liquid Silicone Rubber (LSR) is a process used to produce pliable, durable parts in high volumes. During the process, several components are necessary such as:

- Injector

- Metering unit

- Supply drum

- Mixer,

- Nozzle

- Mold clamp

Molds and dies are essential tools for mass production in today’s manufacturing industry. Both are key elements in manufacturing as they contribute to the mass production of products with the same shape and quality for a faster manufacturing process and lower costs.

- Food manufacturing

- Pharmaceutical

- Oil & Gas

- Electronics

- Tools manufacturing

- Optical

- and more

OUR BLOG