What are PCBN cutting tools made of?

Polycrystalline cubic boron nitride or PCBN cutting tools‘ main material is CBN grains.

Therefore, PCBN cutting tools inherited the properties of CBN, making them excellent cutting tools for machining.

Suggested read: CBN Grinding Wheel For Surface Grinding in Automotive Industry

The properties of PCBN tools

CBN is known for its:

- High strength and wear resistance

- Excellent chemical stability

- Good thermal conductivity and low friction coefficient

High strength and wear resistance

PCBN is the second hardest material after diamond, having similar structure to that of diamond.

Therefore, PCBN tools have high strength and high wear resistance compared to carbide cutting tools and vitrified cutting tools.

So, PCBN tools are excellent for machining tough cast iron and steel. Generally, they are suitable for machining materials with high strength, high hardness and high thermal sensitivity.

Excellent chemical stability

PCBN tools will not react with iron materials even when the temperature reaches 1200 °c to 1300 °c. Plus, it can even withstand high temperature up to 1800 °c.

This is because PCBN has high chemical stability thus making the chemical wear of PCBN tools smaller than others.

Good thermal conductivity and low friction coefficient

The thermal conductivity of PCBN is much higher than that of high speed steel, vitrifieds and cemented carbide. Additionally, the thermal conductivity of PCBN tools increases with the increase of temperature.

This lowers the temperature of cutting tip during machining, which is beneficial to improve the tool durability and prolong the service life of the tool.

When interacting with other materials, the friction coefficient is about 0.1-0.3, which is much smaller than cemented carbide and other materials.

Moreover, they also reduce the cutting force and cutting temperature. Therefore, improving the overall surface machining quality of the workpiece.

PCBN cutting tools machining applications

PCBN tools are used for machining high-hardness materials (tool steel, high speed steel, harderned steel) as well as difficult-to-machining materials (surface coating material, surface hardening alloy).

Gray cast iron

One the common applications of PCBN tools is high speed cutting gray cast iron material.

When machining high speed cutting gray cast iron, the tool life can reach 20-30 times more than vitrified cutting tools.

The ferrite content in the gray cast iron material is normally less than 10%, making it more suitable for the cutting using PCBN tools.

This is because if the ferrite content is high, it will react with the boron element during cutting, thus increasing the chemical wear of the tool and eventually reducing the service life of the tool.

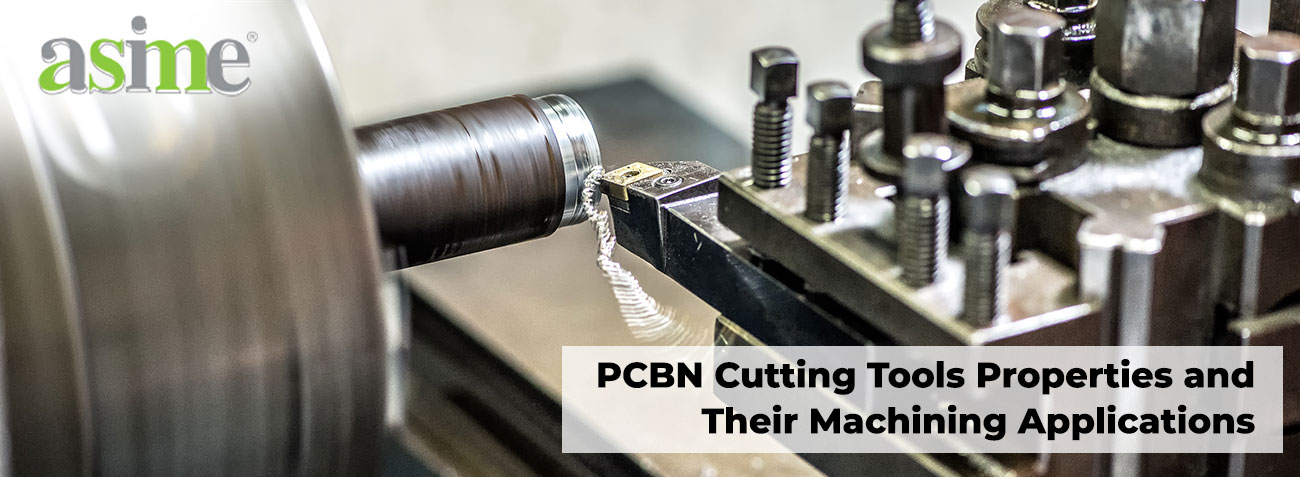

Hardened steel

Hardened steel is a typical difficult-to-machining and wear-resistant material. Therefore, grinding is a common process to finish the finishing of hardened steel parts.

However, when machining hardened steel with PCBN tools, the machining efficiency is faster than grinding.

Plus, PCBN tools are more suitable for cutting parts in different shapes and more flexible than grinding.

Customized PCBN Tools Supplier Malaysia

We suggest you consult ASIME, the ISO Certified Precision Tools manufacturer, with more than 20 years of experience. We speak all high-end customized precision tools manufacturing including custom PCBN cutting tools.

So look no further as we take great care in our manufacturing processes, and are always following DOE and ISO standards. We ensure that our tools and services are nothing short of world-class.