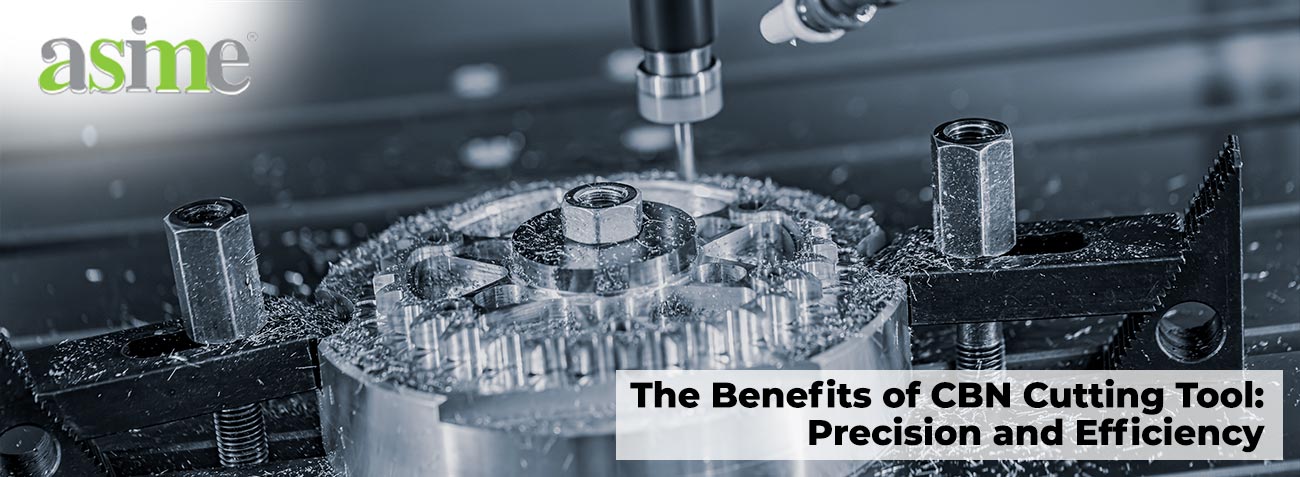

In the world of machining and manufacturing, precision and efficiency are paramount.

Industries such as automotive, aerospace, and medical devices require cutting-edge tools that can deliver exceptional performance while maintaining tight tolerances.

The Power of CBN Cutting Tool for Machining Applications

One such tool that has revolutionized the field is CBN cutting tools.

With their remarkable hardness and durability, CBN cutting tools offer a host of benefits, including unmatched precision and exceptional efficiency.

In this blog, we will delve deeper into the advantages of CBN cutting tools.

Superior Hardness and Wear Resistance

CBN cutting tools are known for their exceptional hardness, surpassed only by diamond.

This remarkable property allows them to withstand high cutting temperatures and resist wear, making them ideal for demanding machining applications.

Besides, unlike traditional cutting tools made from carbide or ceramic materials, CBN tools maintain their sharpness and cutting edge integrity for extended periods.

This results in longer tool life, reduced downtime for tool changes, and ultimately, increased productivity.

Enhanced Precision and Surface Finish

When it comes to achieving precise dimensions and high-quality surface finishes, CBN cutting tools excel.

Their exceptional hardness and wear resistance allow for higher cutting speeds and feeds, enabling faster material removal rates without compromising accuracy.

Moreover, the sharp cutting edges of CBN tools provide clean, smooth cuts, reducing the need for secondary finishing operations.

This level of precision and surface finish consistency is crucial in industries where tight tolerances and impeccable aesthetics are paramount.

Extended Tool Life and Cost Savings

One of the significant advantages of CBN cutting tools is their extended tool life, resulting in substantial cost savings for manufacturers.

The exceptional wear resistance and hardness of CBN tools minimize tool deterioration and the need for frequent replacements.

As a result, manufacturers can significantly reduce their tooling costs while maintaining high machining performance.

Additionally, the longevity of CBN cutting tools reduces machine downtime, further enhancing productivity and overall efficiency.

Versatility and Adaptability

CBN cutting tools also offer versatility and adaptability, allowing them to tackle a wide range of materials and applications.

Whether it’s hard steels, superalloys, cast iron, or hardened materials, CBN tools can deliver consistent performance and exceptional results.

Furthermore, their ability to withstand high cutting temperatures makes them suitable for dry machining applications, reducing the need for coolants and lubricants.

This not only simplifies the machining process but also contributes to environmental sustainability by reducing the use of cutting fluids.

Improved Process Stability and Reduced Scrap Rates

The exceptional thermal stability of CBN cutting tools contributes to improved process stability during machining operations.

With reduced tool wear and minimal temperature-related issues, manufacturers can achieve consistent results and maintain tight tolerances over extended production runs.

The combination of precision, durability, and reliability offered by CBN tools reduces scrap rates and ensures the highest quality of machined components.

Custom CBN Cutting Tool for Precision and Accurary

In conclusion, CBN cutting tools offer unprecedented precision, efficiency, and durability.

Their superior hardness, wear resistance, and extended tool life make them an invaluable asset in various machining applications.

As technology continues to advance, it becomes crucial for businesses to stay ahead of the competition by adopting cutting-edge tools.

At ASIME, we understand the demands of modern manufacturing and are committed to delivering the highest quality CBN cutting tools customized to meet your specific requirements.

Don’t settle for mediocre results when you can achieve excellence with our custom CBN cutting tools.

Our team of cutting tools experts will work closely with you to understand your unique needs and provide tailored solutions that optimize your machining processes.

Experience the difference that precision-engineered CBN tools can make in your operations.

So, contact us today to explore how ASIME can elevate your manufacturing capabilities with our state-of-the-art CBN cutting tools.

Suggested read: PCBN Cutting Tools for Aerospace Industry: Applications and Advantages