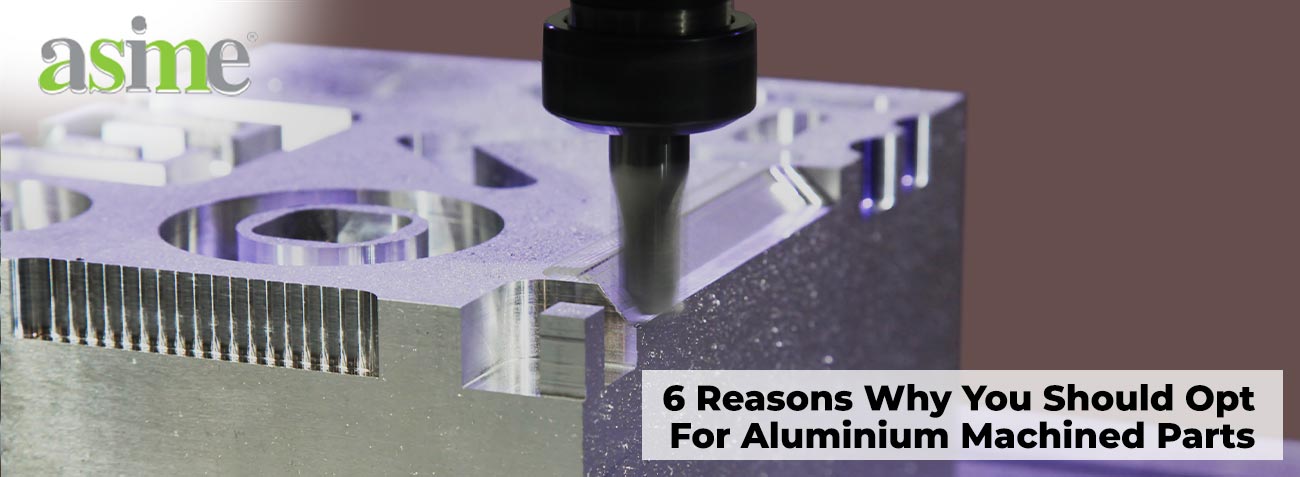

Due to its excellent mechanical properties, many industries look for benefits in working with aluminium to produce aluminium machined parts.

In fact, aluminium comes in second after steel as the best material in CNC machining.

The Impressive Benefits of Aluminium for CNC Machining

When it comes to machined parts, aluminium is one of the leading materials.

There are numerous factors that render aluminium machined parts a very viable solution for numerous industries.

In fact, many of the most popular industries today rely on aluminium machining parts for their applications.

The advantages that aluminium can offer for CNC machining are endless.

Below are a few:

1. Machinability

Aluminium is easy to form, work, and machine, making it ideal for CNC machining applications.

It chips and cuts easily and can be machined with less power than steel.

Furthermore, aluminium’s good machinability means it deforms less during machining than steel does.

This leads to higher accuracy, allowing CNC machines to achieve higher tolerances.

2. Strength-to-weight ratio

The density of aluminium is lower than that of steel, which makes it relatively light.

Despite this, it has a high strength-to-weight ratio, meaning it is both relatively light and strong.

This combination makes it favourable for machining parts required in industries such as the automotive and aerospace industries.

3. Corrosion resistance

Aluminium is corrosion-resistant and scratch-resistant in common marine and atmospheric conditions.

Anodizing can enhance this property.

However, it is important to note that resistance to corrosion varies in different aluminium grades.

The most regularly CNC machined grades have the most resistance.

4. Conductivity

Electrical conductivity in pure aluminium is about 37.7 million siemens per metre at room temperature.

Aluminium alloy may have lower conductivities, but these are sufficient for their parts to find use in electrical components.

However, if electrical conductivity isn’t a desirable characteristic of a machined part, aluminium would be unsuitable.

5. Recyclability

Because CNC machining is a subtractive manufacturing process, it produces a large number of chips, which are considered waste materials.

However, aluminium is highly recyclable and requires relatively low energy, effort, and cost to recycle.

This makes it preferable for those who want to recoup their expenditure or reduce material wastage.

Aluminium’s high recyclability also makes it more environmentally friendly than other materials when machined into parts.

6. Highly Customizable

The most popular reason people choose aluminium machined parts is that aluminium can be customized to typical application requirements.

CNC aluminium machined parts can be beautified or trimmed to specification.

Working with aluminium allows you to create an end product unique to your needs.

Custom Aluminium Machined Parts from ASIME

In conclusion, there is no doubt that aluminium is the optimal material, which explains why it is so frequently used in machined parts.

Likewise, aluminium is one of the best material choices when you need custom machining parts.

They offer the best combination of affordability, flexibility and durability.

Looking for custom aluminium machined parts?

ASIME can help you!

We have specialized in machining parts for over 20 years and have the experience to provide our customers with quality precision aluminium machining parts.

So, contact us today for a FREE consultation!

Suggested read: Types of Cutting Tools for the Aerospace Industry