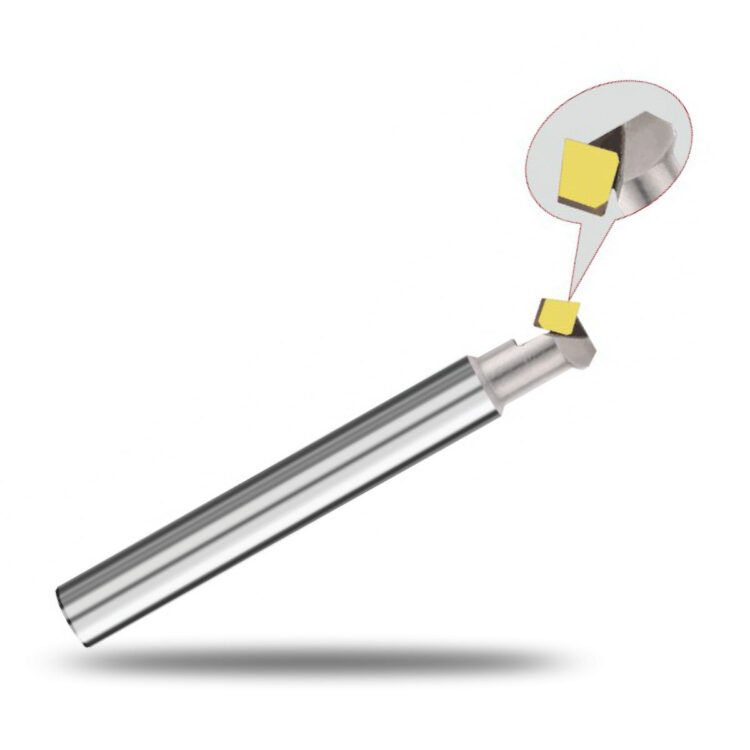

Description

MCD Lettering Tool Primary Uses

Medical Devices

- Engraving lot numbers, UDI codes, and sizing marks on implants (titanium, PEEK) without compromising biocompatibility.

Aerospace

- Permanent part IDs on turbine blades, sensor housings, and CFRP components.

Electronics

- Micro-serialization of ceramic substrates, heat sinks, and connector housings.

Luxury Goods

- Crisp logos on watch cases, jewelry, or high-end audio components.

Optics

- Anti-counterfeit markings on lens edges (< 50µm characters).

Why Choose MCD Lettering Tools?

For mission-critical components requiring permanent, tamper-proof markings that survive extreme environments – medical autoclaves, jet fuel immersion, or space-grade vacuums – MCD engraving delivers crisp, sub-10µm alphanumerics with zero subsurface damage. Ideal when traceability and surface integrity are non-negotiable.

Processing Materials and Applications

Applications: Mobile phone keyway, various high-gloss logos, ultra-high precision and mirror processing.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.