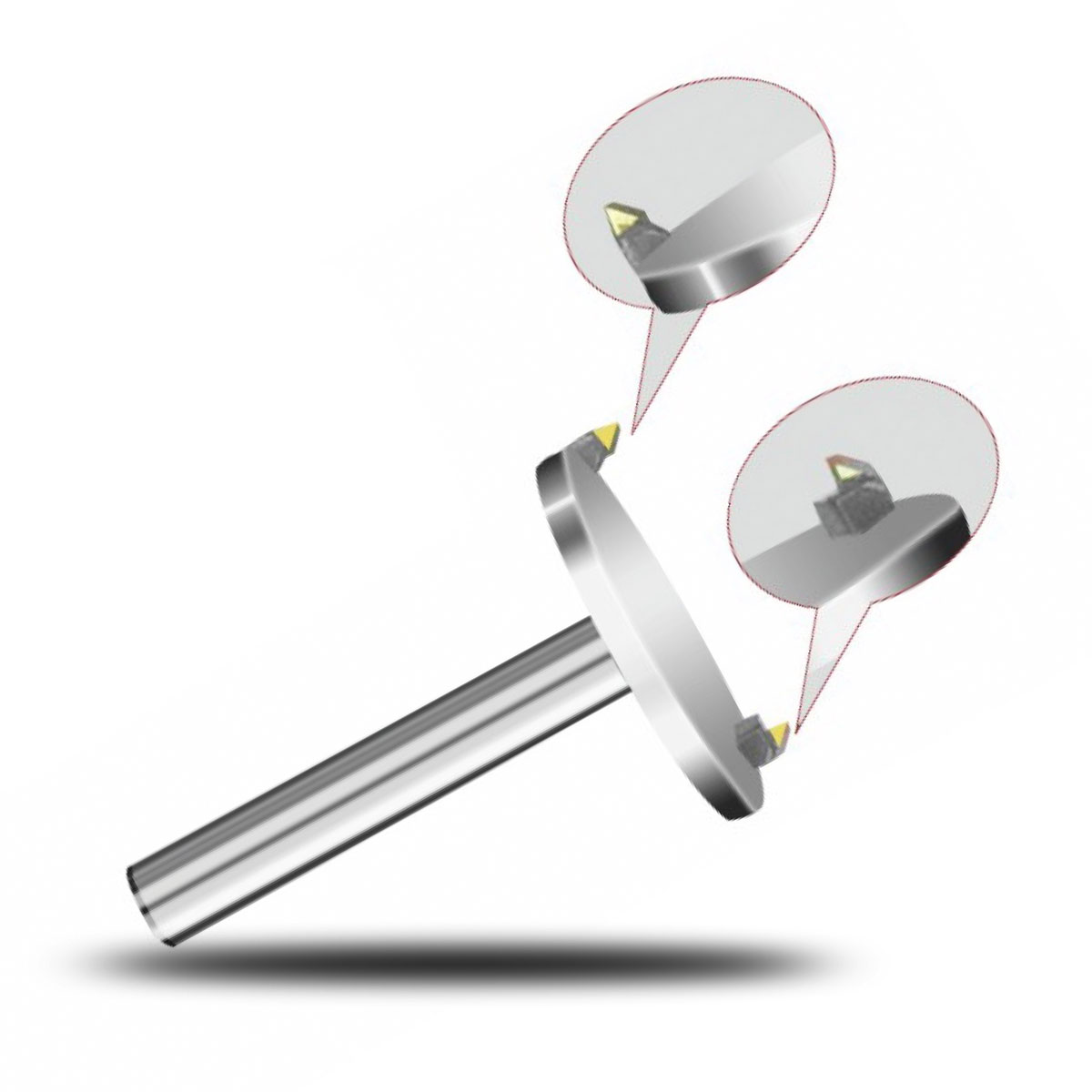

Description

MCD Inserting Tool Primary Uses

Medical Industry

- Use Case: Machining PEEK/Titanium spinal implants

- Benefit: Biocompatible edges, zero micro-burrs

Optics Industry

- Use Case: Diamond turning IR lens molds (ZnSe, Ge)

- Benefit: Ra < 10 nm surface, no tool marks

Automotive Industry

- Use Case: Fuel injector nozzle micro-holes

- Benefit: ±0.5 µm hole consistency, 500+ hrs life

Semiconductor Industry

- Use Case: Edge-profiling silicon wafers

- Benefit: Crack-free chamfers, atomic-scale sharpness

Why Choose MCD Inserting Tool?

For high-value production where tooling flexibility, rapid changeovers, and cost control are critical, MCD inserting systems deliver the performance of solid diamond tools while enabling custom geometry swaps without remanufacturing entire tools. Perfect for medical/aerospace shops running 100+ part numbers.

Processing Materials and Applications

Applications: High-gloass, ultra-high precision and mirror processing of mobile phone middle frame.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

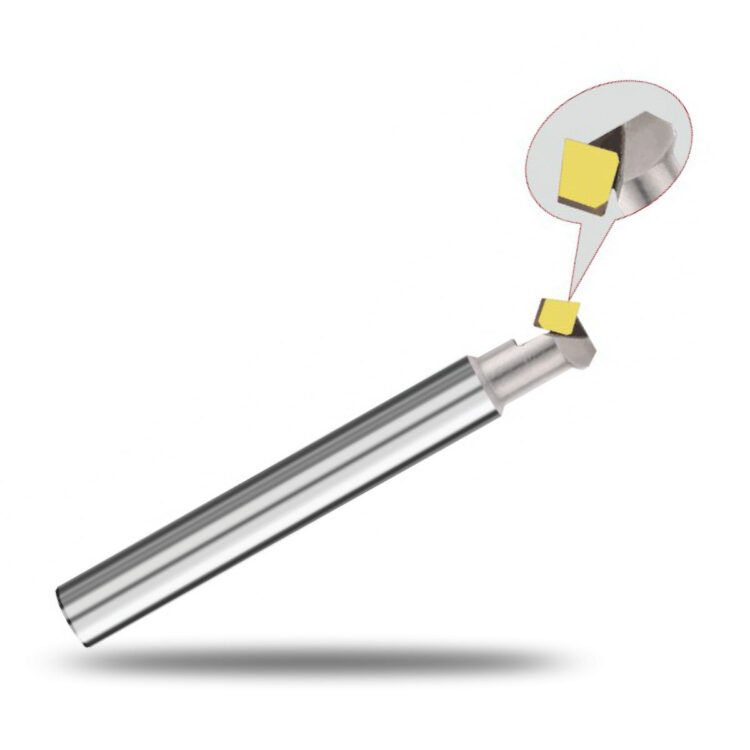

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.