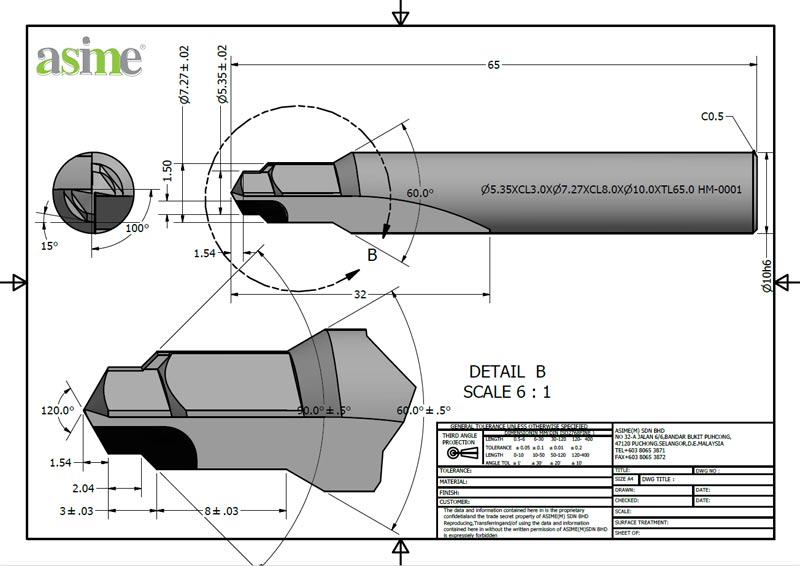

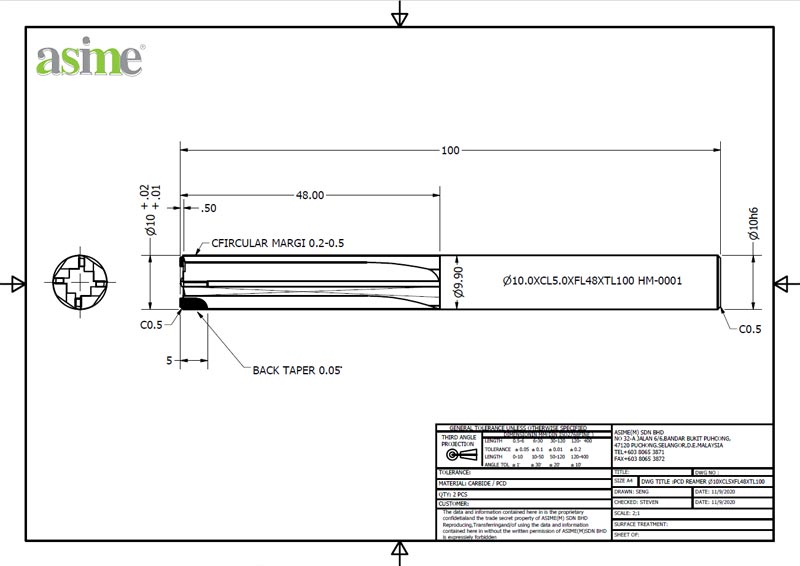

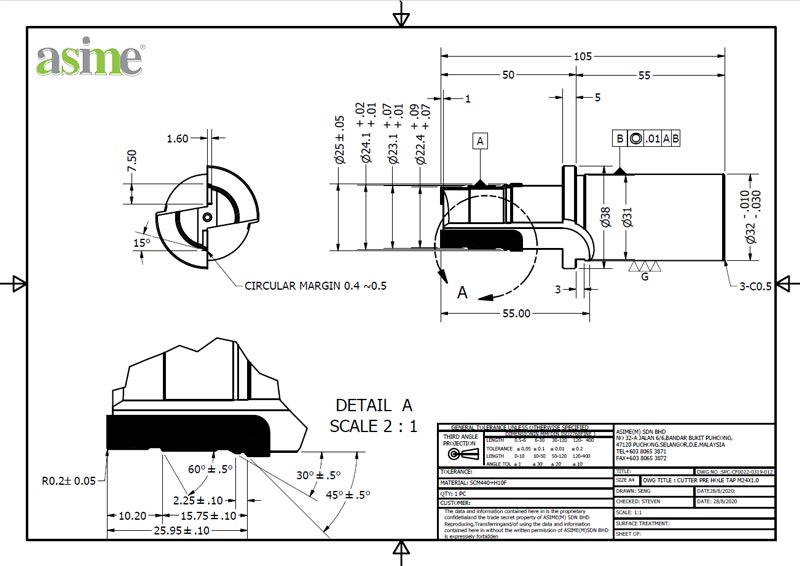

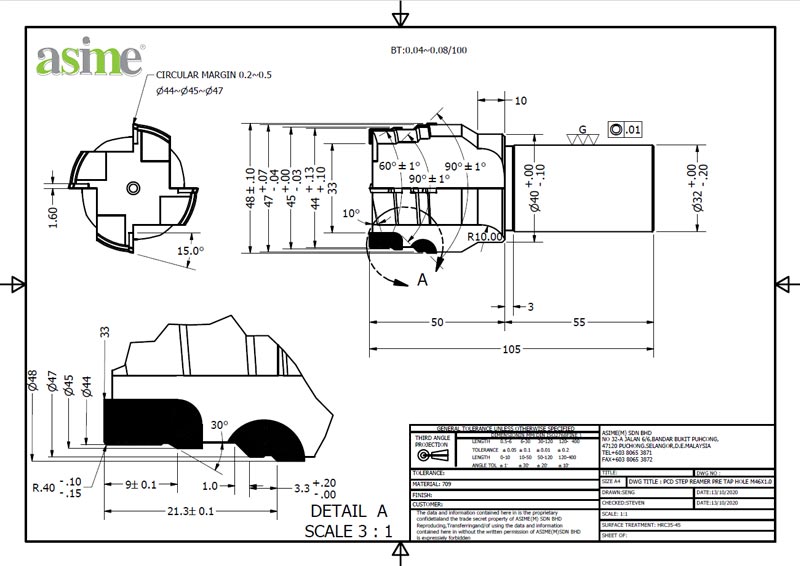

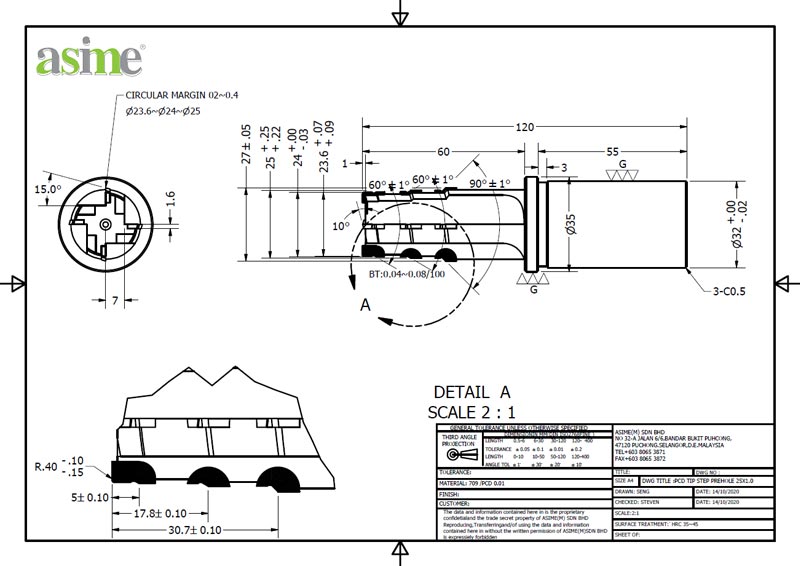

Description

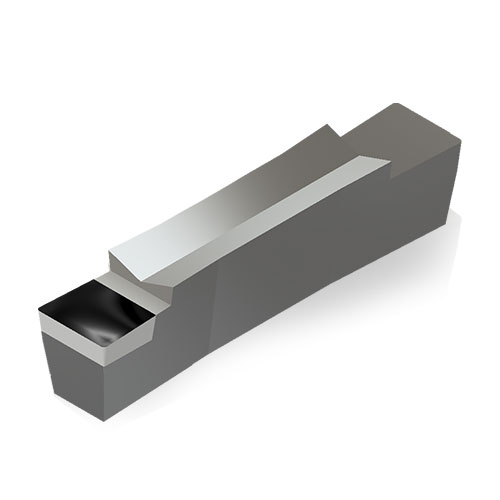

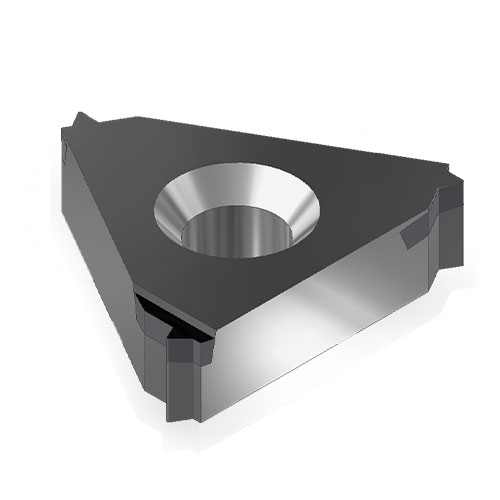

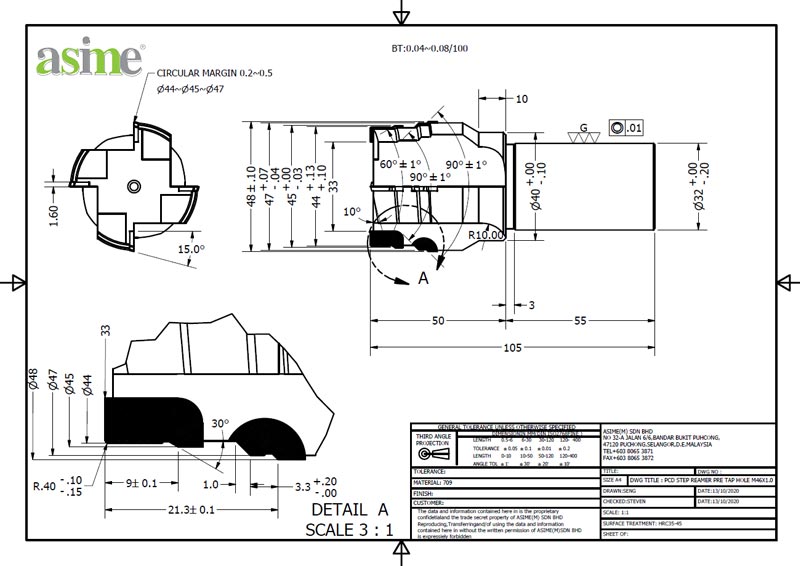

Custom Made Precision Cutting Tools

Asime is able to provide custom made precision manufacturing tool. Below are some of the drawing for your reference:

Grades & Characteristics

PCD - GC001

Applications:

Ideal for milling and rough cutting of aluminium alloys where extreme chip resistance is required, also for machining titanium and composites.

Characteristics:

- Sub-micron grain size.

- PCD-GC001 ultra-fine grain structure is suitable for applications where mirror finishes are required due to its extreme edge sharpness/retention.

Grain Size:

0.5ʯm - 1ʯm

PCD - GC002

Applications:

Ideal for profile routers and thread cutting tools, can also be used in wear part applications.

Characteristics:

- 2ʯm average grain size with increased cobalt for ease of processing.

- PCD-GC002 is ideal for complex tools where excessive processing is required.

Grain Size:

2ʯm

PCD - GC010

Applications:

The ideal grade where roughing and finishing are performed with a single tool. Highly recommended for low to medium content aluminium alloys.

Characteristics:

- 10ʯm average grain size.

- PCD-GC010 is the workhorse PCD grade ideal for many applications where a good balance of toughness and wear resistance is required.

Grain Size:

10ʯm

PCD - GC025

Applications:

Ideal for milling and rough cutting of aluminium alloys where extreme chip resistance is required, also for machining titanium and composites.

Characteristics:

- Average grain size of 25ʯm.

- PCD-GC025 offers the optimum wear resistance for abrasive machining

Grain Size:

25ʯm

PCD - GC030

Applications:

Application areas include MMC, high silicon aluminium alloys, high strength cast irons and bi-metal applications. Excellent abrasion resistance and good thermal stability.

Characteristics:

- A multi-modal PCD with grain sizes of 2ʯm to 30ʯm which gives PCD-GC030 excellent wear resistance, edge strength and edge quality.

Grain Size:

2ʯm - 30ʯm

Grades & Characteristics

PCBN - CB450(Carbide Backed)/BN450(Solid)

Applications:

For moderately interrupted hard turning and finishing hard milling as well as high speed continuous turning. Its resistance to crater wear is among the highest in the market. With one of the finest structures of all commercial grades,PCBN-CB450 provides for sub-ʯm surface roughness.

Characteristics:

- Approximately 50% CBN.

- TiCN Binder.

Grain Size:

0.5ʯm - 1ʯm (Sub-ʯm)

PCBN - CB500(Carbide Backed)/BN500(Solid)

Applications:

For continuous and lightly interrupted cutting of the majority of automotive steels. Excellent abrasion resistance makes it the ideal choice for cold work tool steels and certain valve seat alloys. Also recommended for finishing abrasive high strength cast irons.

Characteristics:

- Approximately 50% CBN.

- Principally TiCN Binder.

Grain Size:

1.5ʯm (Average)

PCBN - CB720(Carbide Backed)/BN720(Solid)

Applications:

For moderate to heavy interrupted turning of all common hardened steels. Provides an excellent balance of toughness, and crater and flank wear resistance. Also used for plunge machining of valve seat rings.

Characteristics:

- Approximately 72% CBN.

- TiCN Binder.

Grain Size:

3ʯm (Average)

PCBN - CB850(Carbide Backed)/BN850(Solid)

Applications:

For application such as grey iron fine boring and valve seat machining, due to excellent strength and abrasion resistance. Ideal for heavily interrupted cutting of all hard and abrasive work piece materials including powder metallurgy components. Proven performance also in hard fine milling applications.

Characteristics:

- Approximately 85% CBN.

- AIWCoB binder for extreme chip resistance.

Grain Size:

2ʯm (Average)

PCBN - CB900(Carbide Backed)/BN900(Solid)

Applications:

Ideal for applications where longer tool life is required. Excels in interrupted machining of grey and hard cast irons, hardened steel milling and in the machining of the majority of valve seat ring alloys. Excellent first choice grade for majority of ferrous powder metals.

Characteristics:

- Approximately 90% CBN.

- Novel binder system to provide the ultimate abrasion and chip resistance.

Grain Size:

4ʯm (Average)

PCBN - CB950(Carbide Backed)/BN950(Solid)

Applications:

For turning and milling of grey and hard cast iron and heavy turning of hardened steels; including components such as brake discs, pump bodies and impellers and large rolls.

Characteristics:

- Approximately 95% CBN.

- Binder phase includes aluminium nitrides and borides.

Grain Size:

-

Thread milling tools are precision tools that are used to cut threads. Thread milling tools are utilized on NC machining centers with simultaneous triaxle control and helical interpolation features.