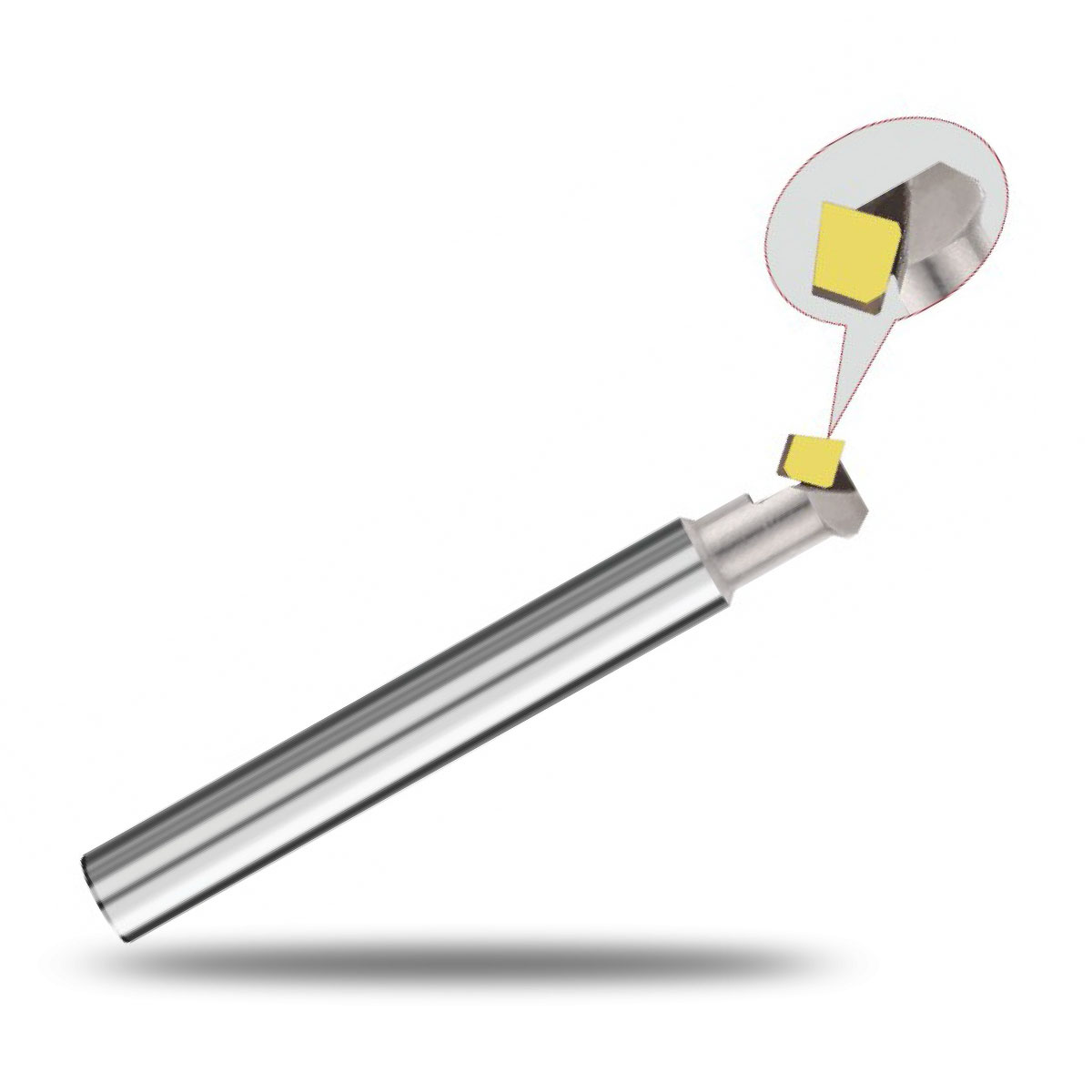

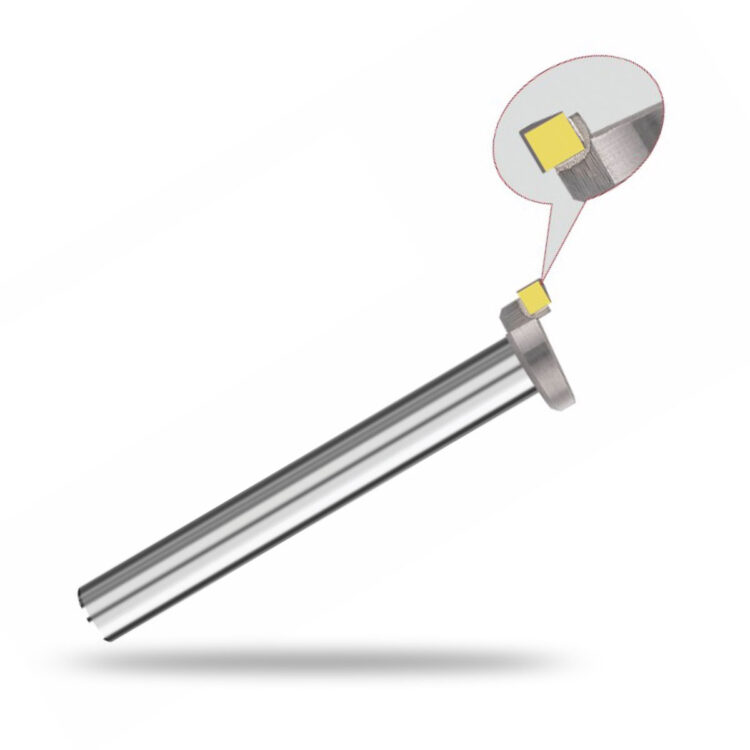

Description

MCD Upper and Lower Chamfering Tool Primary Uses

Medical Implants

- Simultaneous chamfering of spinal rod ends or dental abutments for seamless biocompatibility.

Fluid System Components

- Precision edges on fuel injector nozzles (top/bottom) to prevent turbulence.

Automotive

- Precision chamfers on fuel injector nozzles, valve seats, and sensor housings.

Electronics

- Deburring connector pins (upper/lower edges) without handling damage.

Aerospace

- Critical edge breaks on turbine blade cooling holes.

Why Choose MCD Over Conventional Tools?

For high-tolerance components requiring identical edge quality on multiple surfaces, MCD upper/lower tools deliver synchronized nanometer finishes, eliminate secondary operations, and guarantee lot-to-lot consistency unattainable with PCD or carbide.

Processing Materials and Applications

Application: High-gloss chamfeing in the middle frame of mobile phones, high-gloss chamfering in notebooks, high-gloss chamfering in various cameras, ultra-high precision and mirror processing.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.