Description

MCD Milling Surface Tool Primary Uses

Optics & Photonics

- Machining infrared (IR) lenses, laser optics, and reflectors requiring mirror finishes (Ra < 10 nm).

- Producing defect-free surfaces to minimize light scattering.

Medical Devices

- Machining implants (e.g., orthopedic joints) and surgical tools from non-ferrous materials (e.g., titanium, PEEK).

- Creating biocompatible surfaces with zero micro-scratches or contamination.

Aerospace & Defense

- Finishing gyroscopes, inertial navigation components, and radar waveguides needing sub-micron dimensional stability.

Electronics & Semiconductors

- Milling copper mirrors for EUV lithography, ceramic substrates, and microfluidic chips.

- Achieving burr-free edges on brittle materials (e.g., silicon, germanium).

Automotive Luxury Trim

- High-gloss machining of aluminum, brass, or carbon fiber for dashboards/emblems.

Processing Materials and Applications

Application: For high-gloss, ultra-high precision and mirror processing of mobile phone middle frame.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrious metals and non-metals.

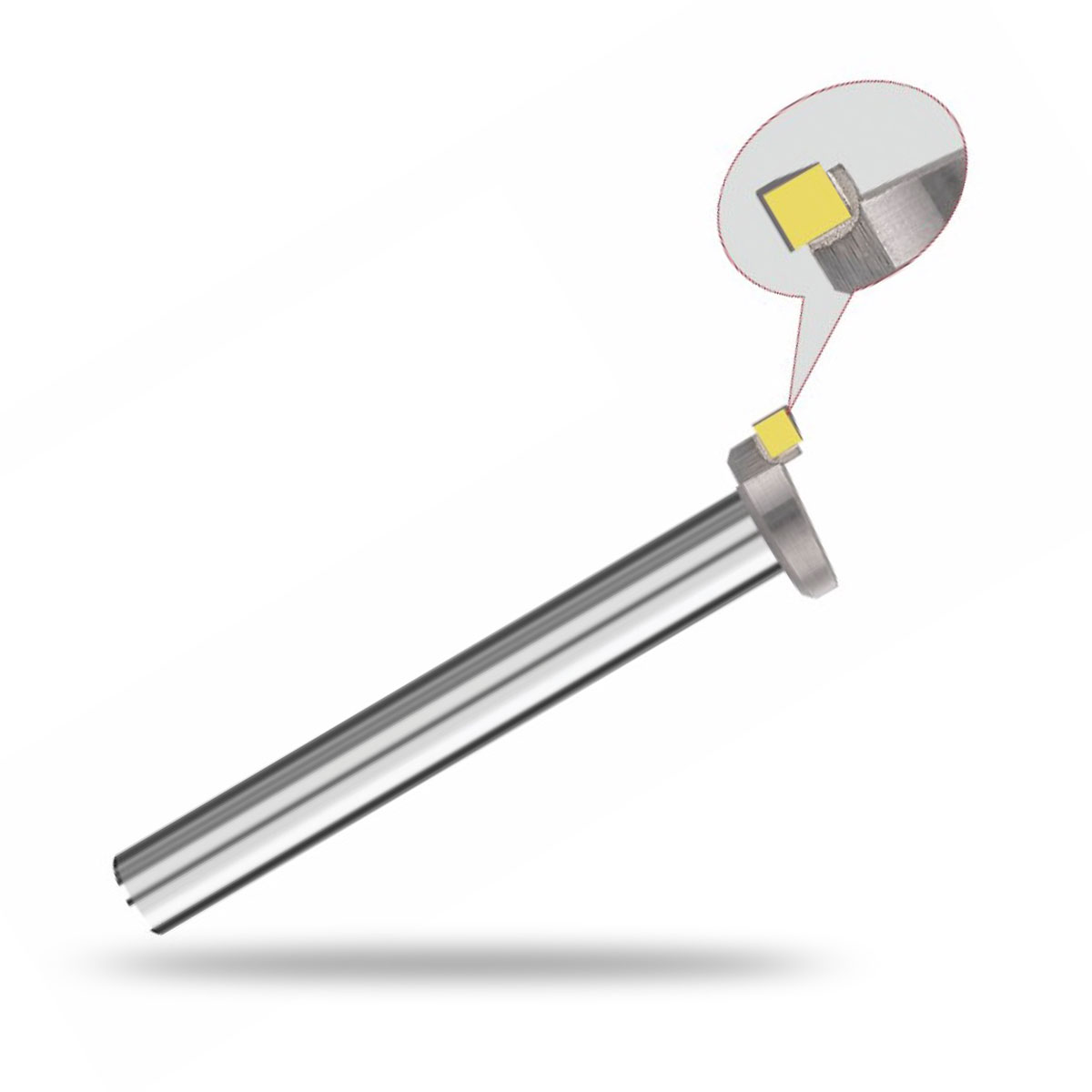

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.