Description

MCD Double Edge Forming Tool Primary Uses

Optics

- Creating aspheric lens molds with synchronized top/bottom curvature.

Medical

- Machining dual-angle spinal screw threads or symmetrical PEEK implant contours.

Automotive

- Forming fuel injector nozzle seats (tapered entry + spherical exit in one pass).

Electronics

- Milling micro-connector channels with matched left/right waveguide profiles.

Why Choose MCD Double Edge Tools?

For high-volume components demanding perfectly synchronized features – like medical implants requiring bilateral symmetry or fluid components needing matched sealing surfaces – these tools slash cycle times while achieving optical-grade finishes unattainable with PCD/carbide. No post-machining alignment or polishing needed.

Processing Materials and Applications

Applications: Optical mould, ultra-high precision and mirror processing.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

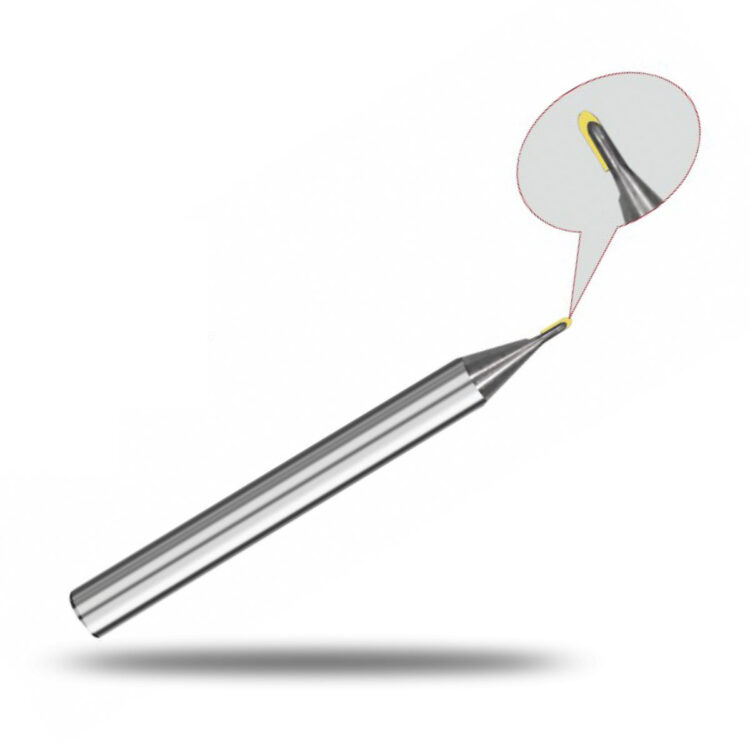

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.