Description

MCD Chamfering Tool Primary Uses

Medical Devices

- Chamfering surgical blades, bone screw threads, and PEEK/Ti implant edges to prevent tissue irritation.

Optics & Semiconductors

- Edge-breaking silicon wafers, sapphire windows, and laser diodes to prevent microfractures.

Automotive

- Precision chamfers on fuel injector nozzles, valve seats, and sensor housings.

Aerospace

- Deburring turbine blade cooling holes and CFRP composite edges.

Why Choose MCD Over Alternatives?

When edge quality impacts function – such as implant biocompatibility, fluid dynamics, or optical performance – MCD chamfer tools deliver zero micro-burrs, nanometer-scale surface integrity, and lifetime consistency unachievable with PCD or carbide.

Processing Materials and Applications

Application: High-gloss chamfeing in the middle frame of mobile phones, high-gloss chamfering in notebooks, high-gloss chamfering in various cameras, ultra-high precision and mirror processing.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

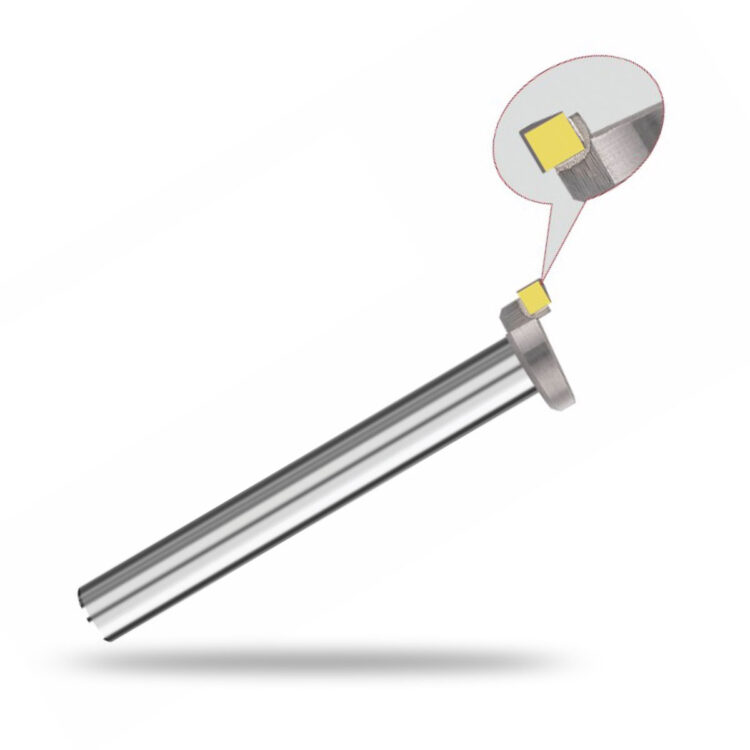

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.