Description

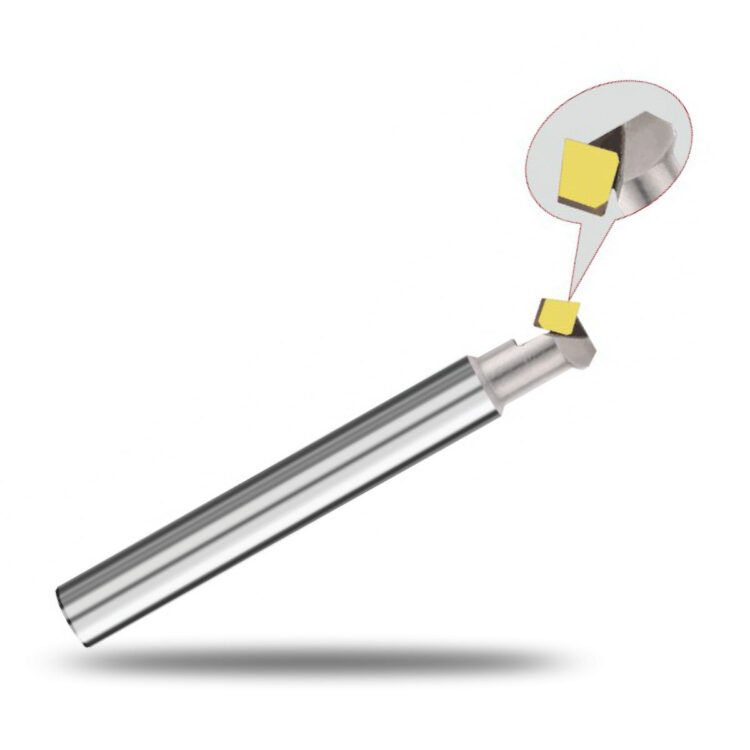

MCD Carving Tool Primary Uses

Optics & Photonics

- Engraving diffractive optical elements (DOEs) and holographic patterns on glass/ZnSe lenses.

- Machining micro-lens arrays for laser systems.

Medical Devices

- Carving microfluidic channels in lab-on-chip devices.

- Texturing implant surfaces (e.g., titanium bone scaffolds) for improved osseointegration.

Decorative & Luxury Goods

- Creating intricate patterns on watch faces, jewelry, or automotive emblems.

- Engraving security markings on high-value components.

Electronics

- Structuring RF waveguide cavities or heat dissipation micro-grooves.

Why Choose MCD for Carving?

When your application demands sub-micron feature fidelity, optical-grade surface quality, and absolute pattern consistency across thousands of parts, MCD carving tools eliminate secondary processes (etching/laser) while delivering unmatched cost-per-part efficiency.”

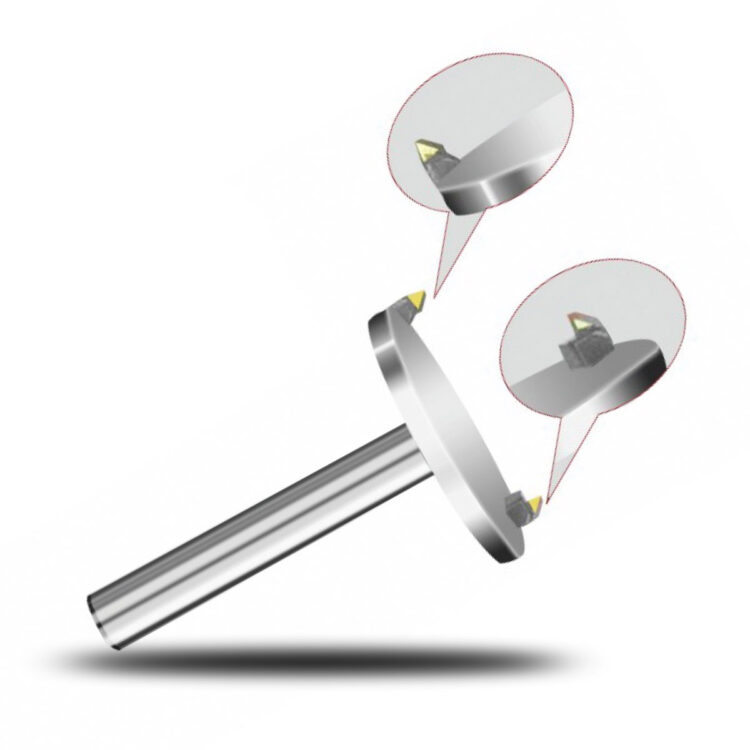

Processing Materials and Applications

Application: Chip, lens highlight, mobile phone button, ultra-high precision and mirror processing.

Processing Materials: Aluminium alloy, copper, plastic and other non-ferrous metals and non-metals.

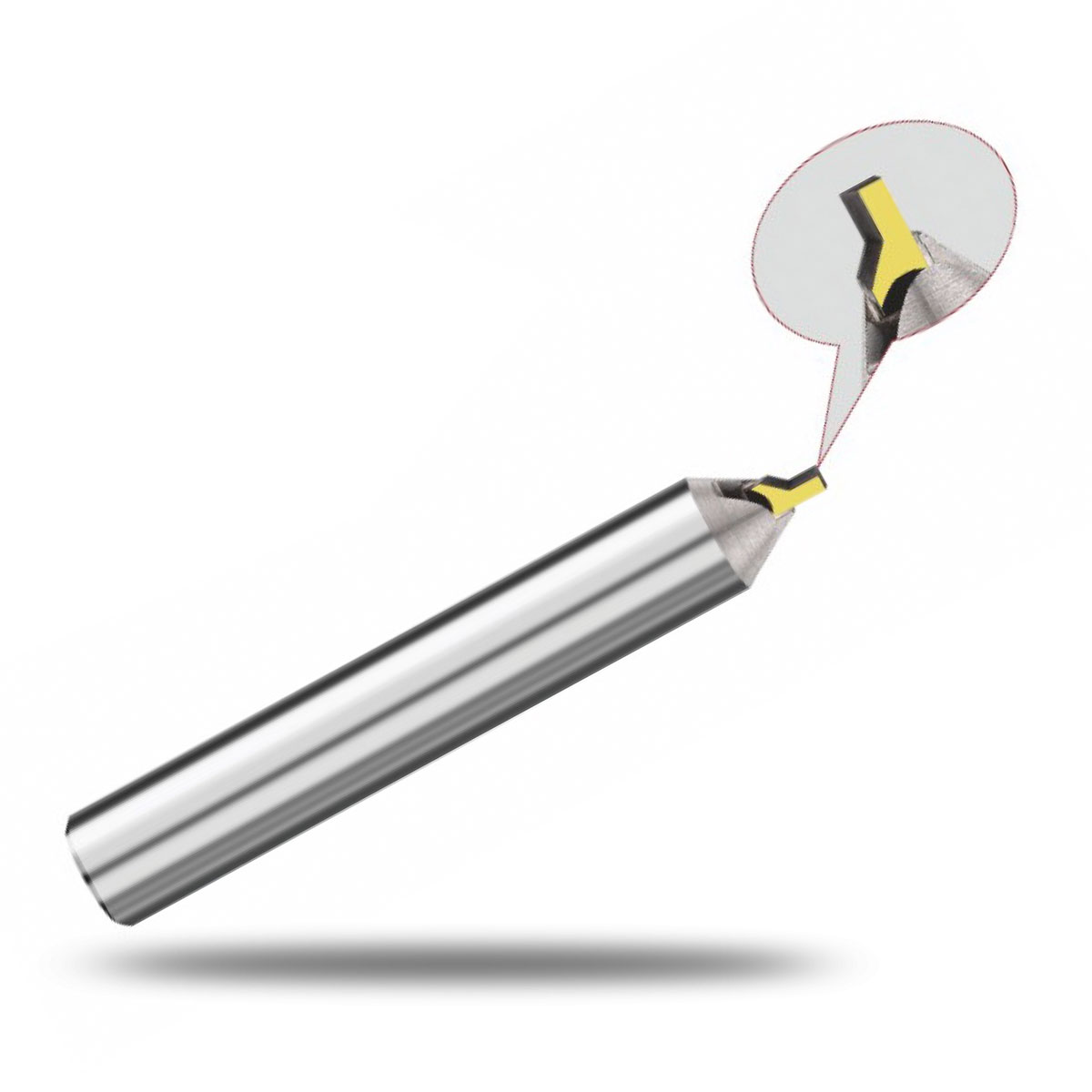

MCD (Mono-Crystalline Diamond) Tools: The Ultimate Solution for Superior Mirror Machining

Unmatched Precision & FinishMCD diamond tools deliver true mirror-like surface finishes, effortlessly achieving sub-micron workpiece accuracy and nanometer-level surface roughness (extremely low Ra values).

Exceptional Cutting PerformanceMachined surfaces exhibit outstanding gloss and uniformity, resulting in a brilliant, mirror-bright finish that significantly enhances product aesthetics and functional performance.

The Benchmark for Ultra-PrecisionLeveraging diamond's supreme hardness, wear resistance, and sharp cutting edge, MCD tools are globally recognized as the ideal and reliable choice for achieving the highest quality ultra-precision machining.