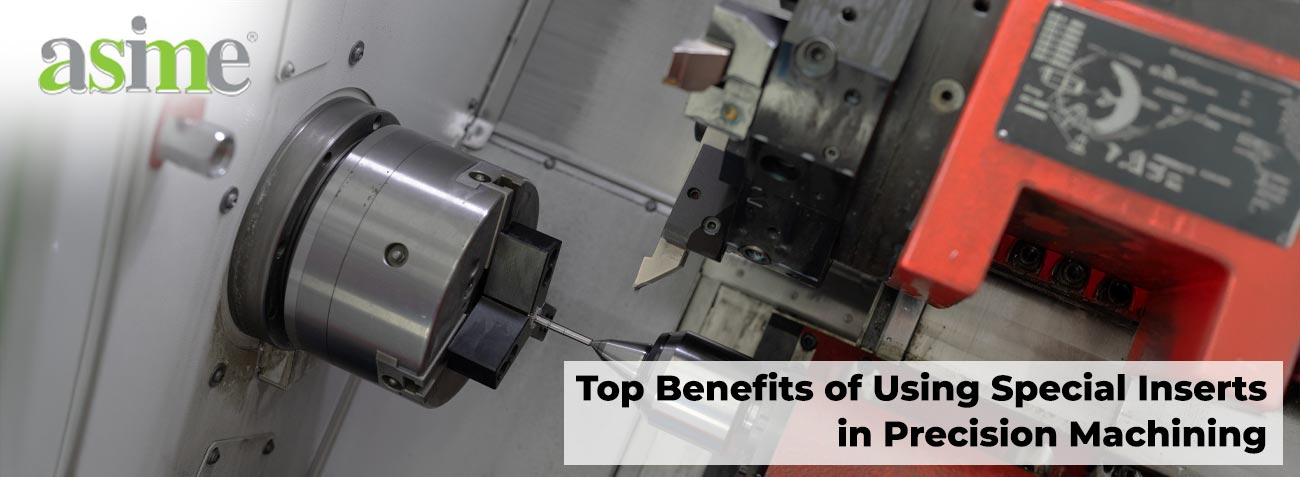

Special inserts in precision machining play an important role in improving efficiency, accuracy, and tool performance across various manufacturing processes.

These inserts feature advanced materials and special designs. Thus, they are built to survive tough environments and to ensure high-quality results every time.

In today’s fast-paced manufacturing environment, the use of customized inserts in precision machining can provide the competitive advantage required to fulfill industry standards.

Let’s now explore the key benefits and performance advantages of using special inserts in precision machining applications.

Enhanced Tool Life and Durability

Special inserts are designed for durability. They often use advanced materials such as carbide, ceramic, CBN, or PCD. These materials offer great wear resistance and strength.

Reduced Downtime

Frequent tool changes slow down operations and increase non-productive time.

Special inserts, with their extended wear life, reduce the frequency of replacements.

Thus, this allows for fewer interruptions and more time for machining. As a result, operational efficiency is higher.

Consistent Performance

Tool wear can reduce surface quality and dimensional accuracy over time.

However, precision machining inserts stay sharp longer. So, this helps operators get consistent results on different workpieces.

Reliability matters a lot in fields that need precision, such as aerospace and medical device manufacturing.

Improved Surface Finish and Accuracy

Precision machining often focuses on achieving a fine surface finish and tight tolerances. So, special inserts are designed to deliver just that.

Precision Cutting

Special inserts are made with exact shapes and sharp edges. They produce cleaner cuts and limit burring.

The accuracy achieved removes the need for extra tasks such as grinding or polishing. This saves both time and resources.

Reduced Chatter and Vibration

Chatter and vibration are common problems that affect surface quality and dimensional control.

Special inserts usually have stronger edges and improved rake angles. These features help cut down on disruptions.

As a result, operators may work with more stability and confidence.

High-Speed Machining

Special inserts can withstand the heat and mechanical demands associated with high-speed cutting applications.

This allows for quicker machining and maintains the surface quality and tool integrity. So, it’s great for high-volume production.

Increased Productivity and Cost-Effectiveness

Special inserts might cost more at first, but the long-term benefits are much more valuable.

Higher Material Removal Rates

Special inserts work well under harsh cutting conditions. Thus, they allow for faster feed rates and deeper cuts.

This results in faster cycle times and more production. Manufacturers can meet tight schedules without giving up on quality.

Reduced Manufacturing Costs

Special inserts help to reduce machining costs. Specifically, they extend tool life, cut down on defects, and lower the need for extra finishing steps.

Their reliability also cuts down the risk of tool failure. If that happens, it could lead to scrap parts or damaged equipment.

Versatility

Special inserts can be made for many materials.

They work with strong metals such as titanium and Inconel, as well as softer alloys and plastics.

Thus, their adaptability makes them a valuable asset in places with varied component needs and strict tolerances.

Optimized Chip Control

Good chip control is key. It keeps tools in good shape, helps them run smoothly, and stops damage to the workpiece and machines.

Efficient Chip Evacuation

Special inserts frequently feature chipbreaker geometries or coatings that enhance smooth chip flow.

In particular, this is crucial in deep cavity or high-volume machining. Chips can pile up fast, leading to overheating or tool jamming.

Reduced Risk of Damage

Poor chip control can cause surface scratches, tool wear, and even machine crashes.

However, special inserts cut these risks down a lot. They have special designs that steer chips away from the cutting zone.

Hence, this keeps the product intact and lowers the risk of rework or part rejection.

Maximize Machining Performance with Special Inserts from Asime

For manufacturers looking to elevate their machining capabilities, investing in special inserts in precision machining is a smart, long-term solution.

So, looking for the right tooling partner? Get in touch with Asime to discover high-performance special inserts tailored to your needs.

Suggested read: Advanced Applications of Router Bits and Ball Nose